Category: Uncategorized

11- Beyond 7 + or – 2: The power of chunking

Quantifying the Limits of Human Information Processing

Early discoveries related to the information processing capacity of human's were welcomed by Applied Cognitive Psychologists, because for the first time they could provide their engineering colleagues with precise numbers. For example, the Hick-Hyman Law and Fitts' Law allowed quantitative estimates of the bandwidth of the human information processing channel (approximately 7-10 bits/sec); and G.A. Miller's famous paper provided a quantitative estimate of the capacity of working memory of from 5 to 9 chunks.

Thus, when the engineers asked how much information to put into a display - the psychologists could provide a number - probably not more than 7 or 9 chunks. However, the smart engineers (and the smart psychologists) were not very satisfied with this estimate. They realized that the numbers were meaningless unless it was possible to specify what constituted a chunk with respect to the domain being represented.

The Power of Chunking

If you read G.A. Miller's paper thoroughly, you will discover that the ultimate conclusion is that, due to the power of chunking, there seems to be no practical limit to the capacity of working memory. Miller describes how a colleague was capable of remembering long strings of binary digits, by using various strategies for recoding them into chunks.

It is a bit dramatic to watch a person get 40 binary digits in a row and then repeat them back without error. However, if you think of this merely as a mnemonic trick for extending the memory span, you will miss the more important point that is implicit in nearly all such mnemonic devices. The point is that recoding is an extremely powerful weapon for increasing the amount of information that we can deal with. In one form or another we use recoding constantly in our daily behavior. (Miller, 1956, p. 95

In this example, the stimulus (strings of binary digits) had no intrinsic structure - so the chunking strategies used were essentially mnemonic tricks (e.g., using an octal coding). That is, the chunking structure is imposed by the observer as an alternative internal representation.

Building on de Groot's observations of chess, Chase and Simon illustrated the power of chunking in relation to expertise. Their research showed that Expert Chess players had superior ability to recall positions after a very brief exposure to a chess game, than more junior players. While the recall of junior players seemed to be in the range of 7 or so pieces, experts could often reproduce the entire game. However, these differences in recall between expert and junior players were essentially eliminated when the recall task involved pieces randomly positioned on the chess board.

It appears that the 'chunking' ability that allowed the superior recall of the experts was dependent on preserving the structure of the game of chess. When the constraints of the game were eliminated, the recall advantage disappeared. This suggests that chunking structure was not an arbitrary mnemonic structure, but rather it was dependent on the intrinsic structure of chess (e.g., the rules of the game, the intentions of the players, the strength or weaknesses of positions relative to winning the game).

Chunking, Attunement, & Coordinative Structure

Perhaps, chunking facilitates memory and problem solving in a fashion analogously to how coordinative structures facilitate motor control. The superior memory capability and the ability of expert chess players to see a good option quickly suggest that they are tuned to the functional constraints of the game of chess, in the same way that a specific coordinative structure might be tuned to accomplish a specific motor function (e.g., see discussion of golf shots in previous post on requisite variety).

With regards to the discussion of requisite variety in an earlier post, the tuning to the functional constraints of the game would tend to make the signals more salient (e.g., the strengths/weaknesses of various positions) and reduce the noise (i.e., possibilities inconsistent with the constraints of the game). When the functional constraints of the game of chess are removed - the advantages of this tuning disappear.

In a similar way, Gibson's ecological optics and the related notion of optical invariance, can also be seen as an ecological basis for chunking. In other words, the optical structure provides a means for tuning into the natural constraints (or natural dimensionality) associated with control of locomotion - making the relative signals salient (allowing direct perception).

This also has clear implications for designing graphical interfaces - as emphasized in Ecological Interface Design. The key is to design representations (e.g., analogs or metaphors) that make the structure or constraints of a process salient. Thus, helping people to tune into meaningful chunks or dimensions with respect to the process control problem. The key challenge then, is to discover the natural structure intrinsic to the process being controlled (e.g., the constraints, laws or invariants). This is the ultimate goal of work analysis (e.g, Vicente (1999).

Chunking to highlight the deep structure of a problem

A key point here is to get beyond the numbers (7 + or - 2) and to get beyond the idea that chunking is a simple mnemonic trick in order to appreciate that it is possible to parse problems into functionally meaningful chunks. This is illustrated by Wertheimer's (1959) concept of productive thinking. He shows that productive thinking depends on representations that parse a problem in terms of its deep structure. The key point is that the practical power of chunking comes when an observer is tuned to and uses the natural structure of the problem (e.g., constraints, patterns, invariants, categories) in productive ways.

10 – The Direct Experience of Quality

Pirsig's Metaphysics of Quality

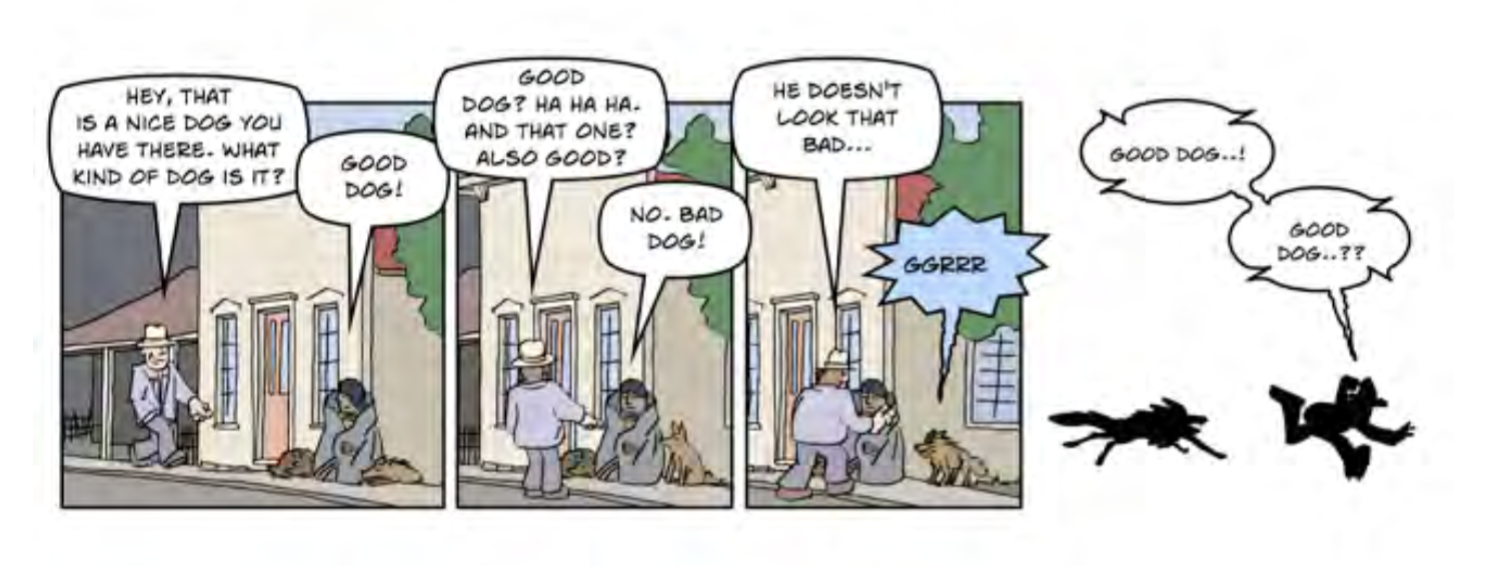

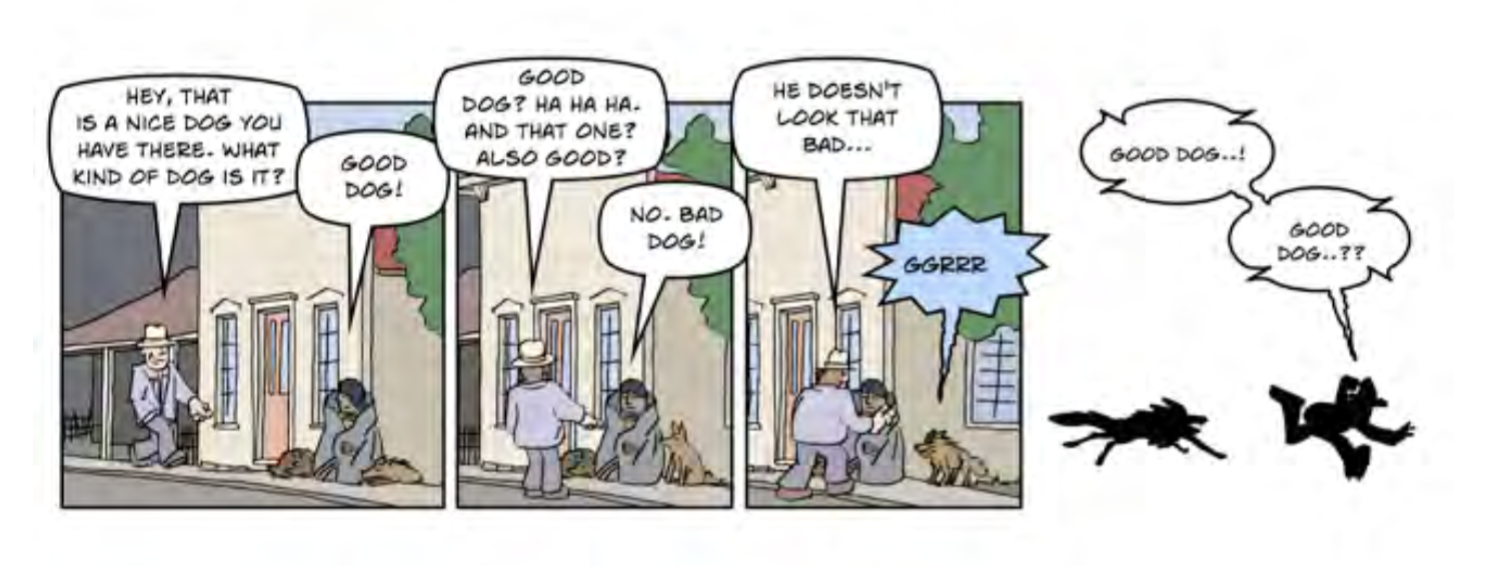

In his second book Lila, Pirsig tells an anecdote about a Native American Indian who responds to a question about the type of a particular dog with the answer "That's a good dog." The questioner laughs at this response, as if the question was not understood. But Pirsig notes that for Native American's "good" is a quality of the dog that can be directly experienced. That is, "good" is not a subjective interpretation, an opinion of the observer, but an ontologically basic property of the experience. In other words, "good" is a property that can be directly perceived.

This is an aspect of the dynamics of circles that is not well appreciated - in addition to affording and specifying - satisfying is fundamental to the dynamics of abduction or adaptive control.

In the classical Western view, properties such as 'goodness' are subjective or derivative. As such, they fall outside of the sphere of science and are relegated to the arts. In pursuit of objectivity, Western science has defined all questions associated with value as irrelevant or extrinsic to its mission to understand reality. The implication is that value is not real. It is not an ontological primitive. It is a derivative property that is open to interpretation.

However, the stability of a system that is intimately coupled with an ecology depends critically on the ability to discriminate between the 'good' (e.g., nutritious, safe, growth enhancing) and the 'bad' (e.g., poisonous, threatening, stifling). Thus, the implication of Pirsig's Metaphysics of Quality is that for the dynamics of experience - qualities such as good and bad are ontologically basic. Much more so than the objective properties of Western Science (e.g., position, velocity, size, weight).

The objective properties of Western Science were specifically chosen to describe a reality that was independent from an observer. However, a science of experience is interested specifically in the properties that relate to stability of the coupling between perception and action (or the coupling between the actor and the ecology). These properties include constraints on action (affording), constraints on perception (specifying), and constraints on value (satisfying). Each specified as duals that depend jointly on properties of the relations between actor and ecology.

It is the constraints on value (satisfying) that determine the attractive potential of the field of experience -- whereas the constraints on action and perception will determine what attractors can be realized and what repellers can be avoided. In other words, the constraints on value determine the relations between the ecology and the health of the actor (e.g., consequences). And the constraints on information and action determine the capacity of the actor to discriminate and control action to realize the healthy consequences and avoid the dangerous consequences.

The key point of the Metaphysics of Quality is that the constraints on value (i.e., what is good and bad; healthy or dangerous) are as ontologically basic to experience as the constraints on action and information. These three types of constraint jointly shape motion through the field of experience.

In relation to the previous post - emotions may be that aspect of experience that reflects attunement to properties associated with value. Falling in love is an example of detecting an attractor. For example, we fall in love with an object (e.g., a house, a car, another person) and then the constraints on perception and action determine whether the object can be obtained or not. A person without emotions is like a boat without a destination - adrift on the seas, fully functional (i.e., controllable) but with no reference for preferring one direction to another.

10 – The Direct Experience of Quality

Pirsig's Metaphysics of Quality

In his second book Lila, Pirsig tells an anecdote about a Native American Indian who responds to a question about the type of a particular dog with the answer "That's a good dog." The questioner laughs at this response, as if the question was not understood. But Pirsig notes that for Native American's "good" is a quality of the dog that can be directly experienced. That is, "good" is not a subjective interpretation, an opinion of the observer, but an ontologically basic property of the experience. In other words, "good" is a property that can be directly perceived.

This is an aspect of the dynamics of circles that is not well appreciated - in addition to affording and specifying - satisfying is fundamental to the dynamics of abduction or adaptive control.

In the classical Western view, properties such as 'goodness' are subjective or derivative. As such, they fall outside of the sphere of science and are relegated to the arts. In pursuit of objectivity, Western science has defined all questions associated with value as irrelevant or extrinsic to its mission to understand reality. The implication is that value is not real. It is not an ontological primitive. It is a derivative property that is open to interpretation.

However, the stability of a system that is intimately coupled with an ecology depends critically on the ability to discriminate between the 'good' (e.g., nutritious, safe, growth enhancing) and the 'bad' (e.g., poisonous, threatening, stifling). Thus, the implication of Pirsig's Metaphysics of Quality is that for the dynamics of experience - qualities such as good and bad are ontologically basic. Much more so than the objective properties of Western Science (e.g., position, velocity, size, weight).

The objective properties of Western Science were specifically chosen to describe a reality that was independent from an observer. However, a science of experience is interested specifically in the properties that relate to stability of the coupling between perception and action (or the coupling between the actor and the ecology). These properties include constraints on action (affording), constraints on perception (specifying), and constraints on value (satisfying). Each specified as duals that depend jointly on properties of the relations between actor and ecology.

It is the constraints on value (satisfying) that determine the attractive potential of the field of experience -- whereas the constraints on action and perception will determine what attractors can be realized and what repellers can be avoided. In other words, the constraints on value determine the relations between the ecology and the health of the actor (e.g., consequences). And the constraints on information and action determine the capacity of the actor to discriminate and control action to realize the healthy consequences and avoid the dangerous consequences.

The key point of the Metaphysics of Quality is that the constraints on value (i.e., what is good and bad; healthy or dangerous) are as ontologically basic to experience as the constraints on action and information. These three types of constraint jointly shape motion through the field of experience.

In relation to the previous post - emotions may be that aspect of experience that reflects attunement to properties associated with value. Falling in love is an example of detecting an attractor. For example, we fall in love with an object (e.g., a house, a car, another person) and then the constraints on perception and action determine whether the object can be obtained or not. A person without emotions is like a boat without a destination - adrift on the seas, fully functional (i.e., controllable) but with no reference for preferring one direction to another.

The Gordian Knot: Why action often ‘Trumps’ logic.

Emotions and Rationality

Conventionally, emotion has been seen as a threat to rationality - where an emotional choice is treated as if it is the opposite of a rational choice. When Descartes split the mind from the body - emotion was linked with the body - not with the mind. Emotions tended to be seen as vestiges of a more primitive brain that had been superseded by the more rational/logical neocortex. To be rational, meant to suppress the emotional urges in favor of more deliberative logic.

However, researchers such as Antonio Damasio are discovering that emotions may be integral to effective decision making and problem solving. In essence the emotions help to ground rationality with respect to the practical value of decisions. Emotions tend to "mark" choices that have high negative or positive value. In this way, the emotions are integral to the process of learning from past mistakes and past successes.

Emotions may also be important in terms of the persistence needed to overcome obstacles to success - particularly when it comes to innovation. Feyerabend suggests that without passion, many innovations in science would have been overwhelmed by the logic of the conventional ways of thinking. The weight of evidence/logic always favors the conventional paradigms -- and it takes time for enough evidence to accumulate to drive a paradigm shift. Thus, success of the new paradigm often depends on the passion to persist against the weight of the conventional perspective.

Also, emotions may help to set 'stopping rules' for analytical thinking. For example, Damasio found that patients with damage impacting the coupling of emotional to logical brain centers can be subject to a paralysis of analysis, where they get caught in analytical deliberations that seem to go on without end - there is always another angle to consider or another piece of data to collect. Thus, emotions may play an important role in triggering actions, particularly in complex situations, where certainty is not possible. In complex environments (e.g., military command and control, medicine), it is rarely possible to reach certainty. At some point, a commander or physician must act before they are overtaken by events or before windows of opportunity close. In these situations, decisive action may be more important that having a perfect plan.

Carl Weick illustrates this with his story about the squad lost in the Alps, who are saved when they discover that they have a map. It later turns out that it was the wrong map. The key is that having the map helped to trigger actions - and that the actions eventually led to successful adaptations. One of the positive aspects of decision heuristics such as those suggested by Gigerenzer is that they tend to be recipes for action. In contrast to normative logic or economic models of rationality, the trigger for action (stopping rule) is often integral to the heuristics.

The point is that decisive action may be critical to success. Rather than waiting to make the right decision, success often depends on acting to make the decision right. Emotional intelligence, rather than logic may be critical in triggering the necessary actions.

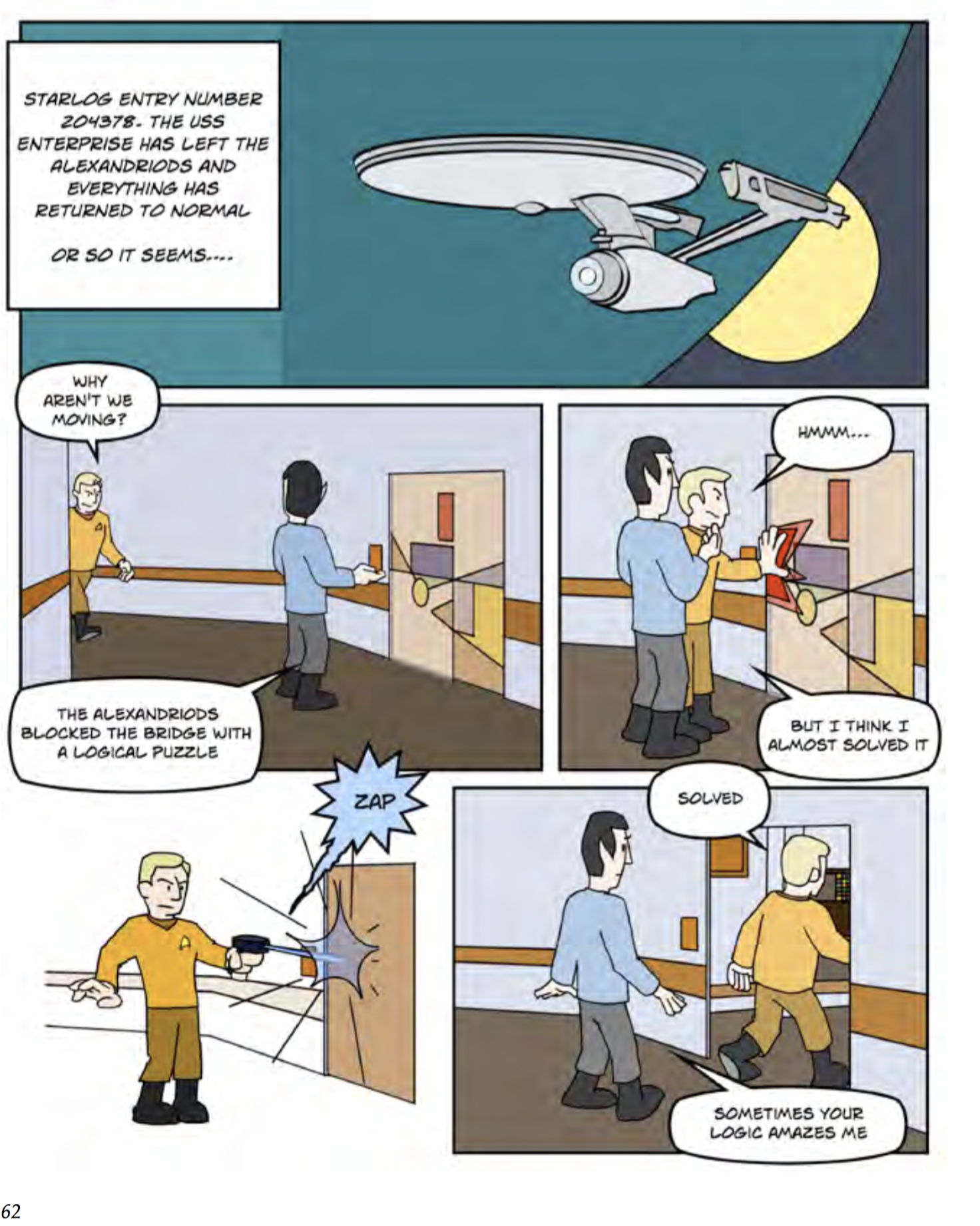

The Gordian Knot

The story of Alexander the Great and the Gordian Knot may be an illustration of the idea of acting to make the decision right. While others debated how best to untie the knot, Alexander acted decisively to solve the problem.

Perhaps, this is one facet of the attractiveness of Trump and his ultimate success in the 2016 election. While the conventional Democrats and Republicans debated over the best way to untie the complex knots that our country was facing, Trump drew his sword and promised action. Thus, Trump's logic was seen as more grounded in terms of action. Whereas, the logic of the conventional political establishment seemed to be caught in a paralysis of analysis - debating how to untie the knot, rather than acting to make things right.

Perhaps many in America were fed up with the logical analysis provided by the media and the conventional politicians. They were looking for action (high energy). They were less interested in whether the logic guiding the action was sound, they were simply tired of analysis and were impatient for action.

Now the ultimate question is not whether Trump's solutions make sense (are they logical)? The only question is will they work? Will Trump's sword cut? If it cuts, no one will be concerned with the logic of how to untie the knots. The ultimate test of a leader is not logical, but pragmatic. Do they get the job done?

Perhaps, the failure of conventional politics is not in the logic of right wing versus left wing. Progress does not depend on who is more logical. It depends on who has the courage to act. Perhaps, the failure of conventional politics today is too much analysis and too little action.

The point is not to to encourage rash action, but to realize that in a complex world there is no certainty without action. No matter how carefully you aim, no target can be hit unless you pull the trigger. And if it's a moving target, you can't take too much time aiming or you miss the opportunity.

Perhaps, in the end it is not about making the right choice, but rather it is about acting to making the choice right.

9 – Requisite Variety

Ashby's Law of Requisite Variety

In discussions about the quality of control (or consistent with the themes in this blog the quality of muddling), Ashby's Law of Requisite Variety is often raised. Basically, this Law states that

for full control, the variety of the controller must me at least equal to the variety of the process or situation being controlled.

In this context, the opposite of variety is constraint. So, an alternative statement of Ashby's Law is that:

for full control the controller must not be more constrained than the process or situation being controlled.

A synonym of variety that is typically used in the motor control literature is degrees of freedom. Thus, a third statement of Ashby's Law is that:

for full control, the degrees of freedom of the controller must be at least as large as the degrees of freedom of the process or situation being controlled.

The gist of Ashby's Law is that if the controller is more constrained than the process being controlled (i.e., has less variety or fewer degrees of freedom), then there will be states of the process that cannot be reached by the controller. In other words, the controller will not be free to access all process states.

Note that failing to satisfy Ashby's Law does not mean that the controller can't achieve satisfaction with respect to controlling the process (e.g., achieve certain goals or avoid catastrophe). It simply means that there are limits to where the controller can take the process. In other words, there are some states of the process that cannot be reached due to constraints in the controller. So, if the controller is more constrained than the process being controlled, then it cannot do anything or everything - there are limits to what states can be achieved and or limits to what process changes can be countered (or maybe even observed).

Typical reasons that a controller might not satisfy Ashby's Law might reflect constraints on perception (observability) or constraints on action (controllability). The control system might not be able to discriminate certain process states from other process states. Or the control system's motor coordination may be too gross to perform the precise moves required to achieve certain state transitions.

Scaling up Variety to meet the challenge of Complex Problems

The natural world is complex or messy and many of the problems that humans or sociotechnical systems must solve in order to survive are ill-structured or wicked. Relative to Ashby's Law, the implication is that the variety associated with these problems can be extremely high.

So, it is quite fortunate that humans are also complex (e.g., the brain has a high degree of freedom), that humans are diverse, and also that we have the ability to use complex technologies. Thus, the variety of an organization of diverse humans and technologies (i.e., a sociotechnical system) can also be extremely high. Although the demands of many complex problems may exceed even the large capacity of the human brain, it will generally be possible for organizations of diverse humans and technologies working together to meet the challenge of Ashby's Law with respect to complex problems. And in many cases the variety of the sociotechnical system may exceed the variety of many complex problems.

On the positive side, exceeding the demands of requisite variety opens up the possibility of full control and also the possibility of redundancy and flexibility offering multiple solutions to control problems. On the negative side, the excess variety within the sociotechnical system may also be a source of 'noise.' That is, the variety within the sociotechnical system may reflect conflicts (e.g., differing values) that make it difficult to coordinate actions to achieve skilled control of the situations. An organization with many degrees of freedom is difficult to manage - like herding cats. Thus, the excess degrees of freedom within the organization (e.g., differing opinions) can add variety, increasing the computational demands on the control system.

While satisfying or exceeding Ashby's Law means that complete control is possible, it does not guarantee that complete or even satisfying control will be achieved. The variety of the controller (or the degrees of freedom or constraints) must be structured to reflect the variety of the process being controlled. In other words, the constraints or structure of the controller must be organized in such a way that it can meet the demands associated with the process. Another way of saying this is that the controller must have a valid internal model of the process. This does not necessarily mean a conscious mental model, but it means that the degrees of freedom in the controller must be tuned appropriately to the demands of the process being controlled.

Degrees of Freedom Problem

In motor control, the tuning of degrees of freedom in the human body to the demands of physical control problems (e.g, playing winning golf) is typically referred to as the degree of freedom problem. While playing winning golf is a high variety problem, each of the different shots required for winning golf are fairly low dimensional problems. But different shots are associated with different types of demand. The requirements for driving a golf ball long distances and staying in the fairway are different than the requirements for chipping a golf ball to a nearer smaller target, which are different than the requirements for putting a ball into a hole.

While the human motor system has adequate degrees of freedom to satisfy the demands of each different shot, it is necessary to use different degrees of freedom (or different constraints) for each type of shot. To be successful at the highest levels, a golfer needs to be able to organize the degrees of freedom of the motor system into different smart mechanisms. Each mechanism reflecting the requisite variety of different situations (e.g., driving, chipping, or putting). In creating these smart mechanisms, different degrees of freedom are 'locked out' (constrained) to reduce the complexity of the control problem.

Thus, for the golfer a key to skilled performance is to lock out unnecessary degrees of freedom (potential sources of noise), leaving a few degrees of freedom that are well matched to the demands of a particular type of shot.

In an analogous fashion, in designing sociotechnical systems focus needs to be on identifying the situational demands of various work functions and creating constraints (e.g., locking out degrees of freedom) to create smart mechanisms for addressing the demands of those functions. This involves setting lines of authority and communication and designing appropriate procedures and representations so that the the organization is well tuned to the problem constraints (or requisite variety). In work domains where the demands are changing - it also becomes necessary to support organizational learning, so that the organization is capable of self-tuning the degrees of freedom to adapt to the changing problem constraints.

Identifying and Designing Constraints

For cognitive systems engineering - an important implication of Ashby's Law is that the focus of work analysis is on identifying the problem constraints. Understanding the problem constraints is a first step toward designing organizations that can achieve satisfying control of complex situations. From the perspective of design - satisfying Ashby's Law is achieved by matching constraints or degrees of freedom. Rasmussen's Abstraction Hierarchy (AH) is one way that cognitive systems engineers try to visualize the constraints in a work domain. Each level of the AH is associated with different classes of constraint (e.g., values, physical laws, regulations, organization, physical function, and physical form).

Diversity within an organization is critical to meeting the requisite variety demands of complex work domains. However, this diversity can also be a source of noise that can make skilled control difficult. Design thinking involves introducing the appropriate constraints to channel this diversity along productive paths reflecting the requisite variety of the problems to be solved (e.g, the shots to be made).

9 – Requisite Variety

Ashby's Law of Requisite Variety

In discussions about the quality of control (or consistent with the themes in this blog the quality of muddling), Ashby's Law of Requisite Variety is often raised. Basically, this Law states that

for full control, the variety of the controller must me at least equal to the variety of the process or situation being controlled.

In this context, the opposite of variety is constraint. So, an alternative statement of Ashby's Law is that:

for full control the controller must not be more constrained than the process or situation being controlled.

A synonym of variety that is typically used in the motor control literature is degrees of freedom. Thus, a third statement of Ashby's Law is that:

for full control, the degrees of freedom of the controller must be at least as large as the degrees of freedom of the process or situation being controlled.

The gist of Ashby's Law is that if the controller is more constrained than the process being controlled (i.e., has less variety or fewer degrees of freedom), then there will be states of the process that cannot be reached by the controller. In other words, the controller will not be free to access all process states.

Note that failing to satisfy Ashby's Law does not mean that the controller can't achieve satisfaction with respect to controlling the process (e.g., achieve certain goals or avoid catastrophe). It simply means that there are limits to where the controller can take the process. In other words, there are some states of the process that cannot be reached due to constraints in the controller. So, if the controller is more constrained than the process being controlled, then it cannot do anything or everything - there are limits to what states can be achieved and or limits to what process changes can be countered (or maybe even observed).

Typical reasons that a controller might not satisfy Ashby's Law might reflect constraints on perception (observability) or constraints on action (controllability). The control system might not be able to discriminate certain process states from other process states. Or the control system's motor coordination may be too gross to perform the precise moves required to achieve certain state transitions.

Scaling up Variety to meet the challenge of Complex Problems

The natural world is complex or messy and many of the problems that humans or sociotechnical systems must solve in order to survive are ill-structured or wicked. Relative to Ashby's Law, the implication is that the variety associated with these problems can be extremely high.

So, it is quite fortunate that humans are also complex (e.g., the brain has a high degree of freedom), that humans are diverse, and also that we have the ability to use complex technologies. Thus, the variety of an organization of diverse humans and technologies (i.e., a sociotechnical system) can also be extremely high. Although the demands of many complex problems may exceed even the large capacity of the human brain, it will generally be possible for organizations of diverse humans and technologies working together to meet the challenge of Ashby's Law with respect to complex problems. And in many cases the variety of the sociotechnical system may exceed the variety of many complex problems.

On the positive side, exceeding the demands of requisite variety opens up the possibility of full control and also the possibility of redundancy and flexibility offering multiple solutions to control problems. On the negative side, the excess variety within the sociotechnical system may also be a source of 'noise.' That is, the variety within the sociotechnical system may reflect conflicts (e.g., differing values) that make it difficult to coordinate actions to achieve skilled control of the situations. An organization with many degrees of freedom is difficult to manage - like herding cats. Thus, the excess degrees of freedom within the organization (e.g., differing opinions) can add variety, increasing the computational demands on the control system.

While satisfying or exceeding Ashby's Law means that complete control is possible, it does not guarantee that complete or even satisfying control will be achieved. The variety of the controller (or the degrees of freedom or constraints) must be structured to reflect the variety of the process being controlled. In other words, the constraints or structure of the controller must be organized in such a way that it can meet the demands associated with the process. Another way of saying this is that the controller must have a valid internal model of the process. This does not necessarily mean a conscious mental model, but it means that the degrees of freedom in the controller must be tuned appropriately to the demands of the process being controlled.

Degrees of Freedom Problem

In motor control, the tuning of degrees of freedom in the human body to the demands of physical control problems (e.g, playing winning golf) is typically referred to as the degree of freedom problem. While playing winning golf is a high variety problem, each of the different shots required for winning golf are fairly low dimensional problems. But different shots are associated with different types of demand. The requirements for driving a golf ball long distances and staying in the fairway are different than the requirements for chipping a golf ball to a nearer smaller target, which are different than the requirements for putting a ball into a hole.

While the human motor system has adequate degrees of freedom to satisfy the demands of each different shot, it is necessary to use different degrees of freedom (or different constraints) for each type of shot. To be successful at the highest levels, a golfer needs to be able to organize the degrees of freedom of the motor system into different smart mechanisms. Each mechanism reflecting the requisite variety of different situations (e.g., driving, chipping, or putting). In creating these smart mechanisms, different degrees of freedom are 'locked out' (constrained) to reduce the complexity of the control problem.

Thus, for the golfer a key to skilled performance is to lock out unnecessary degrees of freedom (potential sources of noise), leaving a few degrees of freedom that are well matched to the demands of a particular type of shot.

In an analogous fashion, in designing sociotechnical systems focus needs to be on identifying the situational demands of various work functions and creating constraints (e.g., locking out degrees of freedom) to create smart mechanisms for addressing the demands of those functions. This involves setting lines of authority and communication and designing appropriate procedures and representations so that the the organization is well tuned to the problem constraints (or requisite variety). In work domains where the demands are changing - it also becomes necessary to support organizational learning, so that the organization is capable of self-tuning the degrees of freedom to adapt to the changing problem constraints.

Identifying and Designing Constraints

For cognitive systems engineering - an important implication of Ashby's Law is that the focus of work analysis is on identifying the problem constraints. Understanding the problem constraints is a first step toward designing organizations that can achieve satisfying control of complex situations. From the perspective of design - satisfying Ashby's Law is achieved by matching constraints or degrees of freedom. Rasmussen's Abstraction Hierarchy (AH) is one way that cognitive systems engineers try to visualize the constraints in a work domain. Each level of the AH is associated with different classes of constraint (e.g., values, physical laws, regulations, organization, physical function, and physical form).

Diversity within an organization is critical to meeting the requisite variety demands of complex work domains. However, this diversity can also be a source of noise that can make skilled control difficult. Design thinking involves introducing the appropriate constraints to channel this diversity along productive paths reflecting the requisite variety of the problems to be solved (e.g, the shots to be made).

Visiting TU Delft (Nov 13-19, 2016)

8 – Incrementalism: The turtle versus the hare.

Social Friction

Have you ever had a fantastic idea that got crushed in discussions with peers and colleagues? Perhaps, the idea was not completely crushed, but it became necessary to compromise and to modify or delay implementation of your idea in order to reach enough consensus for the organization to act on your idea. Or has it ever happened that you later conclude that an idea that you thought was great at one time, turns out to be not so wise and you thank your lucky stars that resistance from within the organization prevented you from making a big mistake. Almost any idea that requires an organization to change course or to try something new or different will come up against resistance (will experience social friction).

In some cases, the social friction will alter or delay implementation of an innovative good idea. But in other cases the friction will result in constructive improvements to the initial idea, and in other cases the friction will prevent the organization from implementing a change that might appear to be a good idea to some, but that would have actually led the organization down a risky or dangerous path.

Essential Friction

Imagine trying to walk or stand on a surface with minimal friction (e.g., on very slippery ice). Under such conditions, maintaining stability can be problematic. On the one hand, friction or drag is considered to be a an obstacle or cost when it comes to movement (e.g., a waste of energy). However, on the other hand, friction can be essential to controlling motion (e.g., maintaining balance and being able to walk to a goal and stop without sliding past). Thus, zero friction is not a desirable condition when it comes to controlling locomotion. As Gene Rochlin has noted:

Without the damping effect of friction, we would live in an impossibly kinetic world in which the consequences of every action would persist and multiply to the point of insanity (p. 132)

Of course, there can be too much friction, such that the energy costs of motion are prohibitive. The bottom line, however, is that some friction is essential for stable, controlled locomotion.

As in the physical world, Rochlin suggests that friction may also be essential to sanity in the social world.

In the realm of the social and political, morals, ethics, knowledge, history, and memory may all serve as sources of "social friction," by which gross motions are damped, impetuous ones slowed, and historical ones absorbed. Such friction is essential to prevent the persistence and multiplication of social and political movements once their driving force is removed (p. 132)

In the social context, an analog to friction might be the opposition and second guessing that tends to arise with any new idea or prospect of change within an organization. A new idea that might at first appear as an innovation, will gradually lose steam in the face of opposition and critiquing. Thus, ideas that are not continually pushed or infused with energy will dissipate, perhaps without ever being implemented. Some of these ideas might have been positive innovations and others might have been simply ill-formed or bad ideas.

Incrementalism

If the abduction or adaptive control logic illustrated in the previous blog (#7) is representative of everyday sensemaking, and if the underlying dynamic is essentially muddling through, then a natural question to ask is: What does skilled muddling look like?

Lindblom's term 'muddling' suggests a messy, chaotic process - a kind of meandering with little chance of convergence. This term stands in stark contrast to the term 'control' and the image of a 'servomechanism' that is the typical image of a control system used in the social sciences. In the servomechanism metaphor there is an implication of a well defined goal and well-defined criteria for comparing the current state to the goal state to yield a well-defined error signal for guiding activity.

However, Lindblom notes that for many public policy decisions there is no single, well-specified goal. Rather there will typically be many competing goals or value systems. In many cases these will be incommensurate relative to each other and only tenuously linked with actions or outcomes, making it difficult to even know when you are on the right track. Thus, with regards to public policy and many important personal decisions (e.g., buying a home, choosing a profession, wooing a mate, voting for a president) there is no a priori well-specified goal or performance standard to specify the right path to a satisfying end. In fact, one might claim that the only reliable metric for judging the quality of a decision or action is the degree of satisfaction with the result. At best, we can recognize a satisfactory solution when we get there - but even that might be questioned (e.g., sour grapes).

However, Lindblom's term incrementalism does suggest something about what quality muddling might look like. This term suggests that quality muddling results from making small (incremental) changes. This suggests a conservative approach that tends to progress through small tweaks to policies that have worked in the past. This strategy progresses through small changes to existing policies, rather than through dramatic innovations.

Stability in Closed-Loop Systems

For the social sciences, the simple servomechanism (e.g., thermostatic control of room temperature) is the prototype of a control system. However, from the perspective of control theory, the simple servomechanism is only one of many solutions for regulating processes. In regulating complex processes (e.g., multi-dimensional), complex control strategies are necessary (e.g., multiple sources of feedback that must be integrated in ways consistent with the process dynamics). In many cases (e.g., when there are long lags in the process or when there are uncertainties about the process dynamics) simple compensatory control (i.e., based on current error feedback) may not yield a stable control solution.

In assessing alternative solutions - particularly for complex processes - the first priority of control theory tends to be stability or robustness. Typical ways to increase the stability or robustness of control solutions is to lower the gain or add damping. In many respects this is analogous to adding friction. The lower gain or damping makes the system more conservative - less responsive to error or deviations from a goal or ideal. It makes the system resistant to change, and reduces any tendency to follow the 'noise' down a garden path to catastrophe.

With respect to gain, good designs trade off speed for accuracy and stability. Lower gain means slower responses - but it also reduces susceptibility to noise or over shooting the target. With respect to robustness, good designs typically trade-off local optimality for stability. That is, a robust controller may not be optimal for any situation, but it will typically be satisfactory for a wider range of situations than a controller that is tuned to be optimal for particular situations.

The prototypical example of a case where a control system is not conservative enough is pilot induced oscillations. This is a situation where the pilot's gain is too high. The pilot overreacts to the errors and the result is that his actions actual result in divergence from the intended target state - often with calamitous results.

Skilled Muddling

Thus, Lindblom's intuitions about incrementalism as a good strategy for dealing with complex sociotechnical problems is consistent with principles derived from control theory. The point is not for organizations to be rigid or completely adverse to change. Change is necessary to keep up with the demands of a changing ecology. However, skepticism and checks and balances with respect to radical new ideas can be essential to skilled muddling. In other words, the friction associated with building consensus within an organization of diverse people with conflicting opinions and values can be essential to the long term success (stability) of the organization.

In order for a control system to be robust in a complex world, a conservative approach to change is generally a good strategy. This helps to ensure that the actions of the organization will generally be responding to the signals (i.e., actual changes in the ecology) rather than the noise (i.e., imagined changes), and that the system will result in satisfactory performance over a wider range of situations. This strategy allows good ideas that are persistently advocated to eventually influence the direction of the organization, while protecting the system against the risks associated with bad ideas and misplaced enthusiasm. The bottom line is that slow and steady progress (i.e., the turtle's strategy) is what usually wins the race in a complex risky world.

Rochlin, G.I. (1998). Essential friction: Error-control in organizational behavior. In The necessity of friction (ed.) N. Ackerman, Boulder, CO: Westview Press. 132-163.